Efficient pump (systems) enable savings potential

When it comes to the purchase of a pump, the focus is on plannable expenses such as investment costs, energy requirements and maintenance (cost of ownership) as well as the safe and reliable operation of the pump itself. In view of rising energy prices, energy consumption is becoming increasingly relevant. That's why it's important to identify potential savings and use pumps efficiently in processes. In practice, however, this means looking at the entire cost of ownership and not only focus on the energy demand.

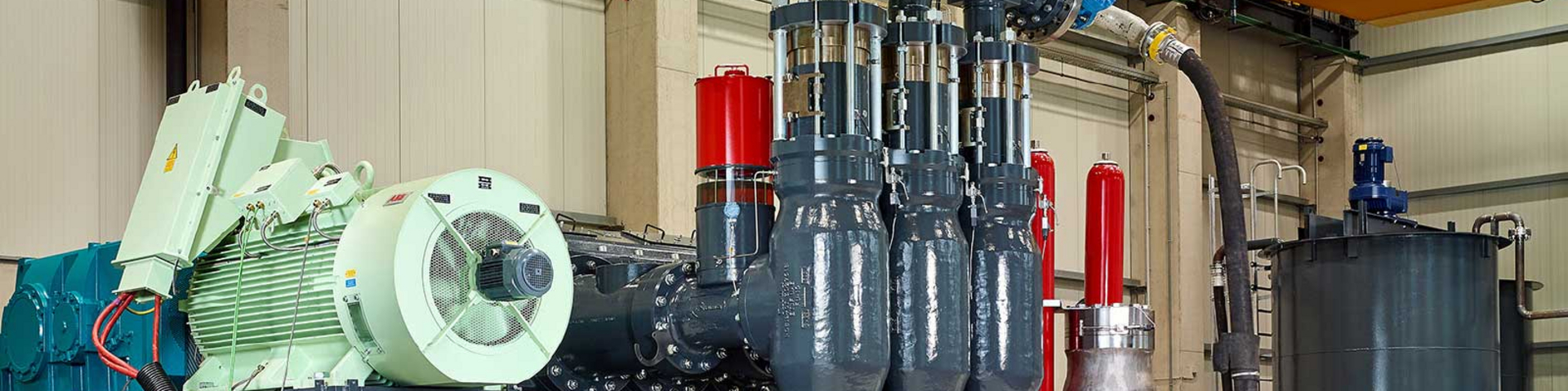

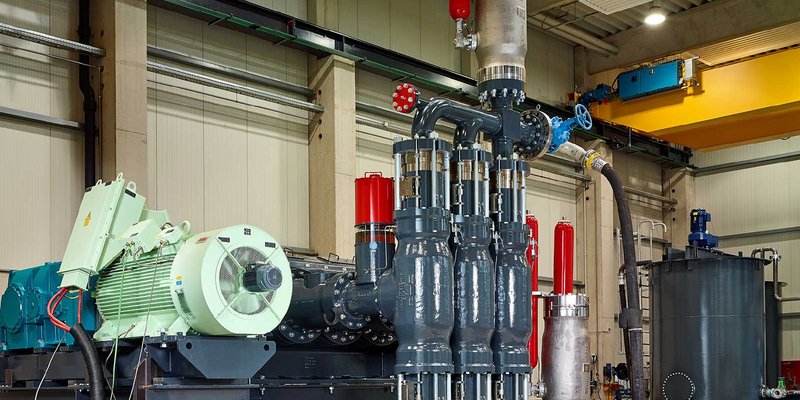

High efficiency of up to 96%

The decisive efficiency advantage of oscillating displacement pumps is the high hydraulic efficiency – it amounts to 96 % for FELUWA MULTISAFE® double hose-diaphragm pumps. For comparison, centrifugal pumps achieve an efficiency of 20-80% which depends on how well or badly the targeted operating point is reached and how far the wear of the impeller has progressed. The reason for the improved performance of piston diaphragm pumps is obvious from a technical point of view: regardless of speed, the piston displaces the same volume with every stroke. Only very low mechanical losses as well as the compressibility of the hydraulic fluid and the pumped medium have to be taken into account. The design-related higher efficiency and independence from a specific operating point creates the basis for an energy-efficient application within a conveying system.

Pulsation Dampening

Another typical characteristic of oscillating displacement pumps is the hydrodynamic independence of the flow rate from pressure and vice versa. This is due to the mechanics of pressure generation. With each piston stroke, the volume resulting from the piston diameter and stroke is reliably displaced and conveyed in the subsequent systems. For one thing, this is how the extraordinarily high hydraulic efficiency of up to 96% is achieved with FELUWA MULTISAFE® double hose-diaphragm pumps. On the other hand, however, the oscillating movement of the pistons sometimes causes flow fluctuations and pulsations. A range of different pulsation dampeners are used to prevent the pressure pulsations. Depending on the actual operating conditions, traditional pressure air vessels with air or gas cushions or pulsation dampeners with hose-diaphragms (PULSORBER) with nitrogen-filled bladder accumulators or rolling diaphragms (PULSORBER 450 or 900) are used at FELUWA.

Pump Synchronisation

If several pumps are pumping into the same piping system, they can be operated and controlled as one unit by means of pump synchronisation. The system operator benefits from maximum flexibility when setting and controlling the volume flow, regardless of the system pressure. The synchronisation not only has a positive effect on the flexibility of the system operator, because he can switch pumps on or off as needed - moreover it allows for the implementation of beneficial and effective standby concepts. The synchronisation of pumps also causes a phase shift hence the resulting pulsation of the pump unit is reduced to a minimum.

Besides energy efficiency, other benefits of pump synchronisation are obvious:

- Reduction of life cycle costs

- Increased efficiency and cost-effectiveness of the entire system

- Constant delivery into piping systems

- Significant increase in the service life of the valves

- Protection of the pump and all downstream systems

Condition Monitoring

However, low energy costs with high efficiency are not sufficient – monitoring of the central components of the pump are crucial. FELUWAs diagnostic systems enable users to monitor the most important parameters and thus allow for predictive maintenance, increased pump availability and reduced operating costs. The possibility of connecting the pump in its standard configuration directly to the control room allows for remote diagnostics and necessary maintenance to be scheduled in line with the operating sequence.

Potential for Savings

Thus, you can work the switches for a low “cost of ownership” when selecting the pump type and design. MULTISAFE® double hose-diaphragm pumps are always the right choice, due to their high overall efficiency and low energy and maintenance costs. FELUWA offers plant operators immense savings potential by using energy-efficient pumps and, with the option of pump synchronisation, maximum flexibility for plant engineers.