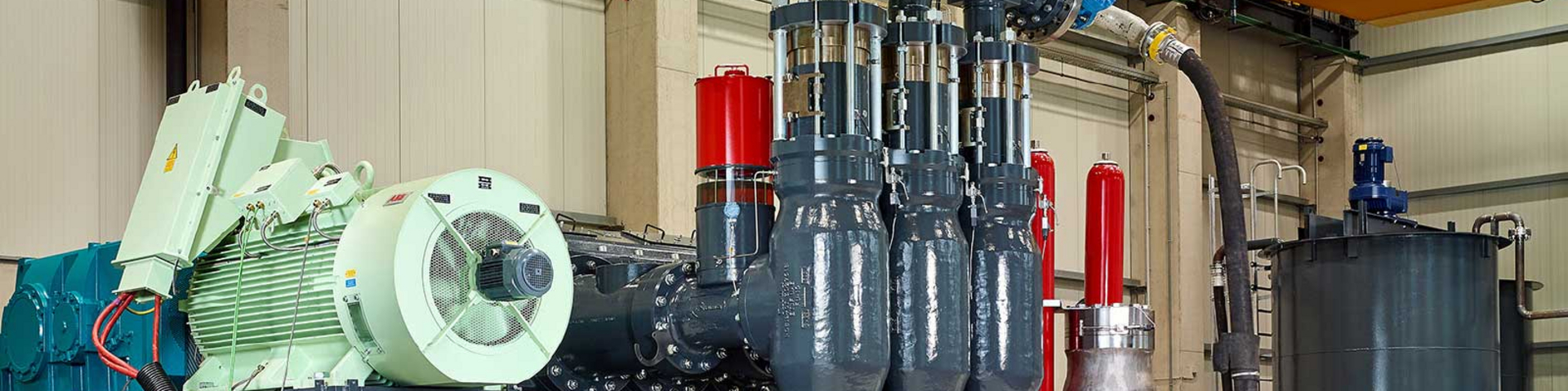

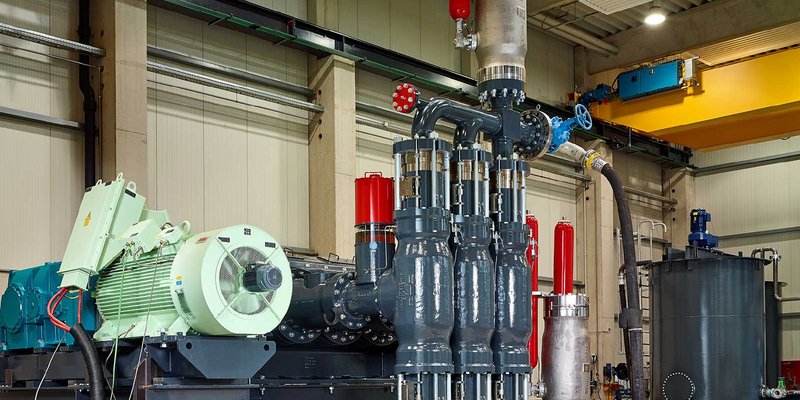

FELUWA References Autoclave Feeding

Ensured process safety in conveying abrasive, aggressive and solids-containing fluids to feed autoclaves and digestors for the processing of minerals.

Advantages FELUWA MULTISAFE® Pumps

- Maximum system availability by a reduced number of wear parts

- High wear resistance of the small number of wetted parts guarantees operational safety

- Adaptability to challenging chemical conditions is achieved by a reduced number of wear parts

- Wide range of available materials for hose-diaphragms and valves

- Hermetical separation between wet end and drive end

| Reference Example | |

|---|---|

| Pump type | TG 130 - 3 DS 35 DFT |

| Volume rate | 17 m³/h |

| Operating pressure | 38 bar |

| Medium | Sulphuric acid with pyrite and SiO2 |

| Wetted parts | 1.4462 / NBR |

| Country | Russia |

| Reference Example | |

|---|---|

| Pump type | TGK 300 - 3 DS 180 |

| Volume rate | 125 m³/h |

| Operating pressure | 40 bar |

| Medium | Bauxite alkali slurry |

| Wetted parts | Carbon steel / NBR |

| Country | Russia |

| Reference Example | |

|---|---|

| Pump type | SG 135 - 2 DS 100 |

| Volume rate | 95 m³/h |

| Operating pressure | 55 bar |

| Medium | Ni-Am-Sulphate Slurry |

| Wetted parts | 1.4462 / EPDM |

| Country | Australia |

Media currently handled for this application

Bauxite alkali slurry, nickel sulphate slurry, sulphuric acid with pyrite and SiO2, zinc sludge

Contact us

Daniel Hagnbuchner

Regional Sales Manager

- +49 (0) 6594 10 109

- +49 (0) 152 22 66 66 44

- hagnbuchner@feluwa.de