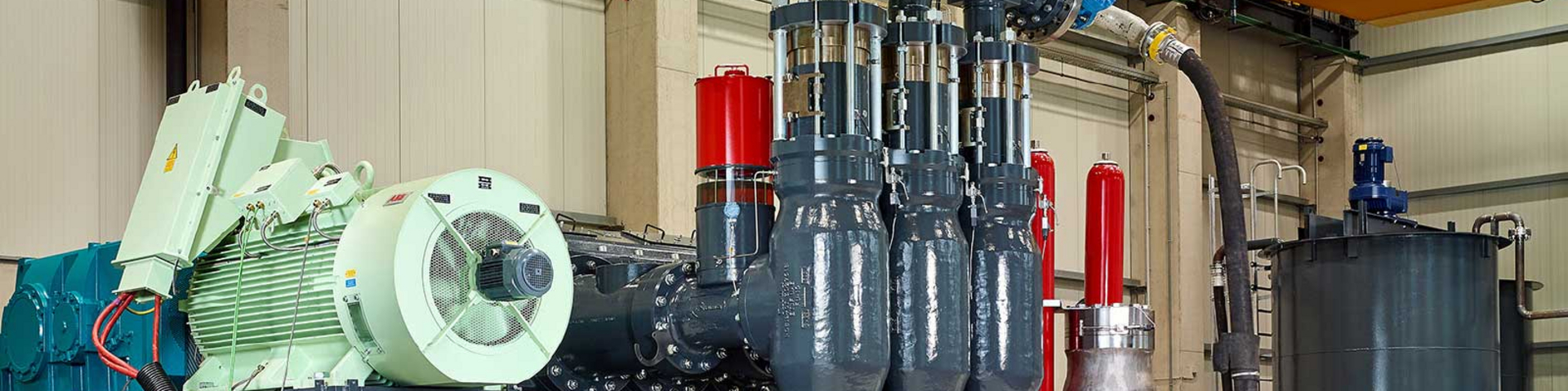

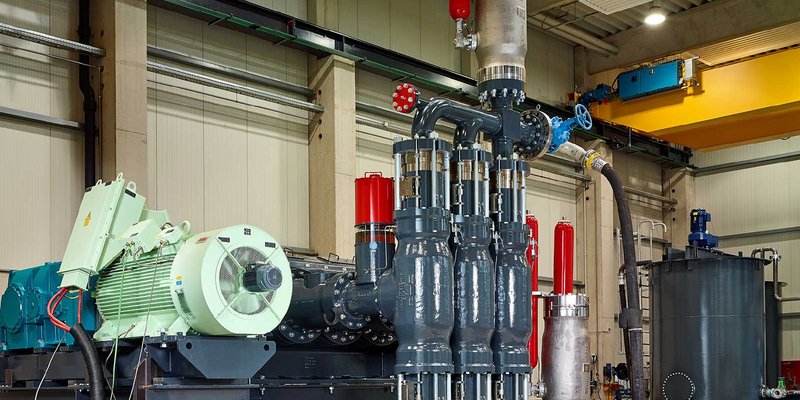

FELUWA References Reactor Feeding

Challenging feeding of pressure vessels in the chemical and petrochemical industry or wet oxidation for the processing of waste.

Advantages FELUWA MULTISAFE® Pumps

- Maximum system availability due to a reduced number of wear parts

- Chemical resistance ensured by small number of wetted parts

- Wide range of available materials for hose-diaphragms and valves

- Human and environmental safety

- Hermetical sealing between wet end and drive end

| Reference Example | |

|---|---|

| Pump type | TG 70 - 3 DS 1 |

| Volume rate | 0.65 m³/h |

| Operating pressure | 275 bar |

| Medium | Waste water |

| Wetted parts | 1.4571 / FPM |

| Country | USA |

| Reference Example | |

|---|---|

| Pump type | TG 135 - 3 DS 35 |

| Volume rate | 19 m³/h |

| Operating pressure | 75 bar |

| Medium | Hydrated lime slurry |

| Wetted parts | 1.4571 & 1.4581 / HNBR |

| Country | United Arab Emirates |

| Reference Example | |

|---|---|

| Pump type | TG 100 - 3 DS 1 |

| Volume rate | 0.5 m³/h |

| Operating pressure | 300 bar |

| Medium | Wood slurry |

| Wetted parts | Carbon steel / NBR |

| Country | USA |

Media currently handled for this application

Aluminium hydroxide, barium ferrite slurry, BASO4 suspension, cobalt carbonate, conditioned thickened slurry, hydrated lime slurry, hydrochloric acid, isobutanol, municipal digested sludge, nickel slurry, pharmaceutical slurry, sewage sludge, sulphide slurry, TDI waste material, wastewater sludge, wood slurry

Contact us

Nicolas Cailloux

Regional Sales Manager

- +49 (0) 6594 10 139

- +49 (0) 152 22 66 66 53

- cailloux@feluwa.de